Packaging Materials

This section outlines the packaging materials we keep stocked for fulfillment. We offer a curated selection of standard mailers and cartons. We also carry an assortment of larger, nonstandard sizing that is available for an additional charge. Standard, non-branded packing tape and filler materials are also available.

💡 Please note: our Pick & Pack pricing takes into account a number of factors, including your packaging preferences. While we consider all factors when calculating your pricing (sales volume, inventory size, etc), shipping exclusively in mailers may result in a lower Pick & Pack rate. Shipping exclusively in cartons may, conversely, result in a higher Pick & Pack rate.

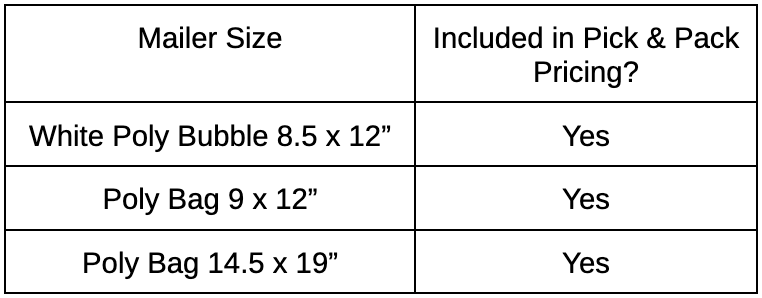

Standard Mailers

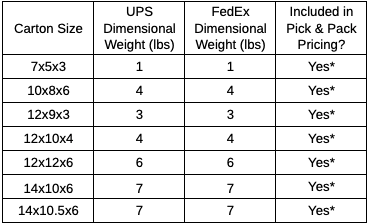

Standard Cartons

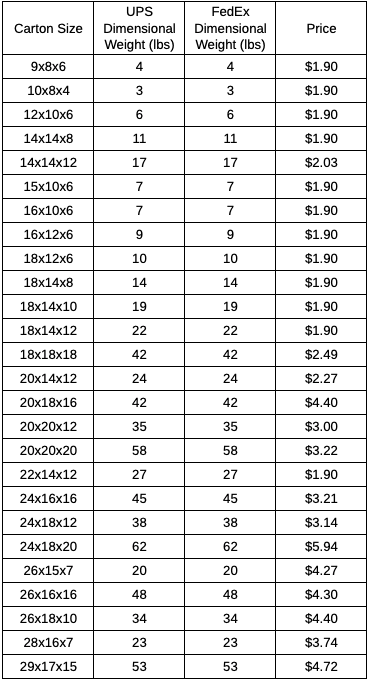

Non-Standard Cartons

*This list contains our most commonly used box sizes. Ship Essential can modify the non-standard assortment as needed.

The box sizes you carry won’t fit my product. Is Ship Essential able to stock the box sizes I need?

If your shipments require box sizes or other materials outside of our standard offerings, just let us know. We’ll do our best to source the appropriate packing materials for you. You may be invoiced for the cost of the materials. Some packaging materials may not be supported due to operational complexity. Custom packaging storage is invoiced monthly at a rate of $45 per month per pallet (1 pallet minimum).

What is dimensional weight and why should I care about it?

Dimensional weight is the amount of space a package occupies in relation to its actual weight. For each shipment, you are charged based on the dimensional weight or actual weight of the package—whichever is greater.

Why is dim weight important? Major shipping companies, including UPS and FedEx, use dim weight to calculate shipping prices. Dim weight pricing may reduce shipping costs for customers who pack more efficiently. Reducing packaging can make shipments more environmentally friendly by helping lower fuel emissions, and can help you avoid overpacking, which wastes material.

To calculate dim weight, carriers multiply the length, width, and height of a package using the longest point on each side. They then divide the cubic volume by a divisor to calculate the dimensional weight in pounds.

Dim weight pricing can reward customers who eliminate extra, oversized packaging. By increasing the shipment density, the carriers can pack more products on trucks and planes.

How do your packers select boxes when they are packing my orders?

Box sizes are not guaranteed but our packers measure the item(s) in each order to determine the optimal mailer or box size of the available options. If multiple box sizes would work for a particular order, they’ll default to the box size that has the lowest dimensional weight.

We also have the ability to assign box sizes to each of your SKUs, eliminating the need for measurement at the packing station. Going this route can help you reduce your shipping costs and speed up your fulfillment. If your products are all the same or very similar in size (eg. you sell t-shirts that are all packed the same way), this can be easily achieved. If your products vary widely in size, standardization is much more difficult.

Let us know if you have particular requirements for packing and we’ll establish workflows and automations to ensure that your orders are packed to your specs.